Laser scanning technology significantly impacts the mining industry by enabling the creation of high-resolution, detailed 3D models of mine sites and underground environments. These models provide valuable insights into geological formations, ore bodies, and infrastructure, leading to improved decision-making in various aspects of mining operations. Moreover, laser scanning allows for accurate measurement and monitoring of excavation progress, facilitating efficient planning and execution of mining activities.

- 3D modeling offers numerous benefits to the mining industry, such as

- Improved workplace safety through hazard identification

- Increased efficiency in ore body delineation

- Accurate planning and design of infrastructure

As laser scanning technology continues to evolve, its applications in mining expand further, revolutionizing the industry's ability to operate safely, efficiently, and sustainably.

Enhancing Mine Operations with 3D Laser Scanner Technology

Modern mining operations depend on cutting-edge technology to maximize efficiency and safety. Among these innovations, 3D laser scanner technology has emerged as a transformative tool for optimizing various aspects of mining activities. By capturing highly accurate 3D models of mine sites, these scanners deliver valuable data that can be utilized to enhance planning, extraction, and monitoring strategies.

- Applications of 3D laser scanner applications in mining include:

- Geological mapping for precise representation of rock formations and potential hazards.

- Site planning and design, allowing for efficient resource allocation and reduction of environmental impact.

- Resource monitoring to monitor material quantities and support efficient logistics.

- Risk assessment by locating potential dangers and establishing appropriate safety protocols.

Streamlined Asset Tracking with 3D Scanning Technology

Modern businesses are increasingly demanding efficient methods to manage their assets in real-time. 3D scanning technology is gaining traction as a transformative solution, providing detailed representations of physical assets. These 3D scans allow the creation of digital twins, which can be employed in real-time asset monitoring and inventory control systems.

- Strengths of using 3D scanners for asset management:

- Improved Accuracy: 3D scans capture minute details, eliminating human error in assessment.

- Real-Time Tracking: Digital twins provide a live view of asset positions, facilitating efficient utilization.

- Streamlined Inventory Management: Automatic recognition of assets through 3D scans simplifies inventory audits and reduces stock discrepancies.

Moreover, 3D scanning data can be leveraged for other applications, such as maintenance planning, asset lifecycle management, and fraud prevention. As the technology evolves, its impact on asset management practices will become even significant.

Precision Geospatial Mapping for Mining Applications with Lasers

Laser scanning technologies are revolutionizing the mining industry by enabling accurate geospatial mapping. This technique utilizes laser pulses to capture millions of points per second, creating a highly refined 3D model of the terrain and structures within a mine site. The resulting maps provide invaluable insights for various mining operations, including site planning.

- Benefits of laser scanning in mining include:

- Improved safety by identifying potential hazards.

- Streamlined mine planning and design.

- Minimized operational costs through accurate measurements.

Leveraging 3D Laser Scanning for Enhanced Safety in Mines

In the demanding environment of mines, ensuring the safety of personnel is paramount. Innovative tools are continuously being implemented to here mitigate risks and enhance workplace security. 3D laser scanner data analysis has emerged as a valuable tool for optimizing safety measures within mines. By recording detailed geometric representations of the mine environment, these scanners provide valuable information that can be used to pinpoint potential hazards and implement targeted safety protocols.

- Specifically, 3D laser scanner data can be processed to visualize underground formations, helping to foresee potential ground instability or collapse risks. This allows for the adoption of preventative measures, such as strengthening of weak areas, thus reducing the likelihood of accidents.

- Moreover, these scanners can be employed to track the movement of equipment and personnel within the mine. This real-time data can assist in maintaining safe distances between vehicles, workers, and potential hazards, thereby lowering the risk of collisions or injuries.

- In conclusion, 3D laser scanner data analysis provides mines with a powerful tool for optimizing safety by identifying potential hazards, enforcing preventative measures, and monitoring activities in real time. This approach has the capacity to significantly reduce accidents and create a safer working environment for all personnel involved.

Leveraging Digital Twins for Predictive Maintenance in Mining via 3D Scanning

The mining industry is constantly seeking innovative solutions to enhance efficiency and safety. One such breakthrough has been the implementation of digital twins for predictive maintenance. By creating a virtual representation of operational machinery using 3D scanners, mining companies can accurately monitor its performance. This instantaneous data allows for the identification of potential issues before they worsen, decreasing downtime and maintenance costs.

- Point cloud generation

- Predictive analytics

- Condition assessment

This strategy empowers mining personnel to make timely decisions, optimizing the overall safety of mining operations.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Jennifer Grey Then & Now!

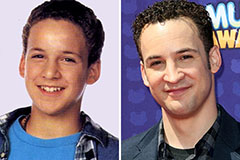

Jennifer Grey Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now!